There is a bit of a story behind how this whole blanket thing came to be. Last Summer I was casting about for ways to insulate the two yurts I was putting up. One of the yurts had a vinyl cover and the other had potentially no cover at all. I knew that I would need a lot of insulation when a great deal came along: hundreds of yards of polar fleece from the failed product line of a local apparel company.

Here it is - many, many yards of polar fleece, at least twice as much as I could use, but it was an all-or-nothing deal, and too good to pass up even if I only used half of it.

I did some tests, layering a few pieces of it on the roof and walls of the vinyl yurt to see how much insulation it would require. When the fires came, these "scraps" of fleece found their way into my blanket trunk and came out to pile on top of the bed during a few exceptionally cold nights. This stuff is super high quality and COZY!

As time went on, I had a little bug in my ear, reminding me to look for a good way to put the excess fleece to good use, especially the bright colors that I don't want in my home.

Then one day I was as the General Store and heard Karen, the cashier, talking about how Santa was coming to bring presents to the kids of Wolf Creek. Many of these kids come from situations where they don't have much to look forward to in this season. A group of locals asks the kids to write letters to Santa and ask for what they'd like. Then they do their best to raise money and give these kids a good Christmas.

I made it halfway across the street to my studio before I realized that I might be able to help. I went back and asked Karen how many kids they were talking about.

"Around 130," was her answer. I did a little math and then told her that I could give her 140 polar fleece blankets for Santa to give the kids along with whatever they were asking for. I had no idea that her face could light up so bright! She was absolutely ecstatic at the idea.

I had no concept of how to cut 140 blankets from those rolls of fleece, so I planned to spend an entire day with scissors, cutting and folding, cutting and folding.

When I showed up, Dan, the production specialist at Select Designs, ran me through what we were about to do. He said that we could cut 70 blankets at a time. What!? I've got to see how this is done.

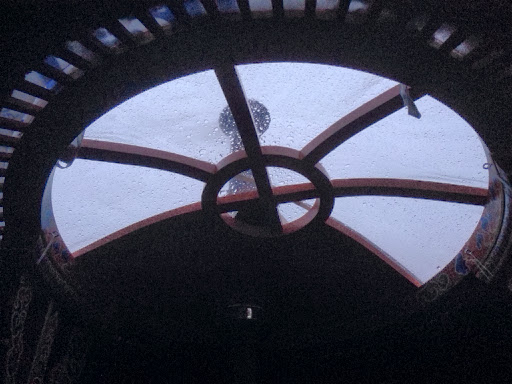

First, Dan and I unrolled layer after layer, two blankets long, onto the massive cutting table. It's easy when you have all the right tools and two people to get the cloth unrolled perfectly flat! You'll notice that the edge is not exactly even. Just watch!

Once we had 35 layers down, aided by a hand clicker that Dan used to keep track, we marked out the cut lines. Then Dan got out the big boy tool, a power knife that can cut through six inches of cloth at once. Cool! Terrifying!

70 blankets down, 70 to go. Yeah, there's a little waste, but the time savings more than makes up for it.

In a little over an hour they were all cut and it was time to fold them for delivery. This took way longer than the cutting.

Halfway done...

et voilá! 140 blankets, ready for Santa to give out to the kids of Wolf Creek.

And here's what's left - a few scraps of color that I'll be donating to a local animal shelter and a few rolls of neutrals that I'll be using on Cloud Nine for insulation, drapes, and more.

Wow, I actually spent so long writing this post that Santa Claus has already come and given out the blankets to all the kids of town. I was having so much fun hanging out with my friends that day that I almost forgot to take a picture of the event. (There are a lot more kids in this room and running around outside than it looks like.) On the right-hand side, you'll notice the lady with long grey hair. That's Karen, who helps this whole event to become a reality every year. Thanks, Karen!